Maximum machining size(mm): 3000*1500*50

Size(mm): 2150*1000*1500

Power(kw): 4

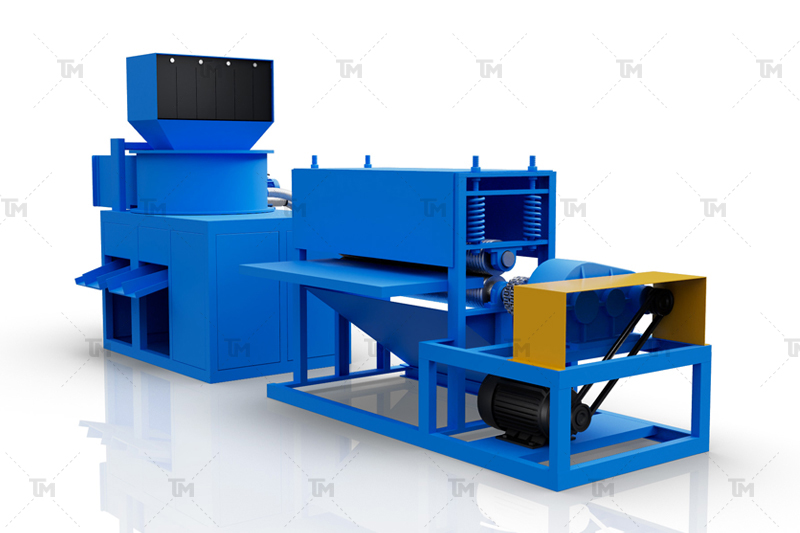

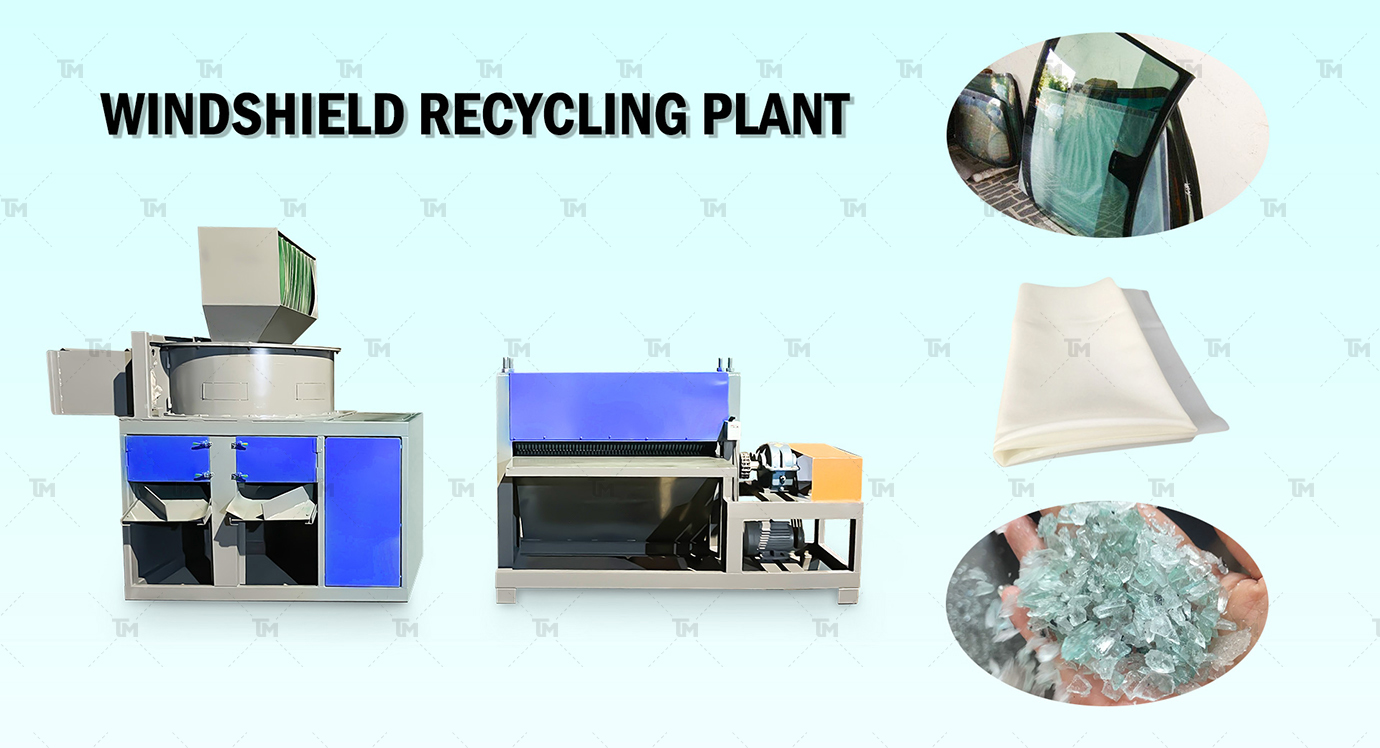

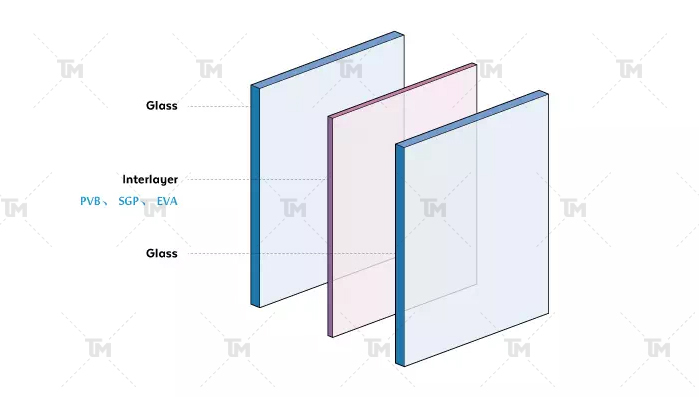

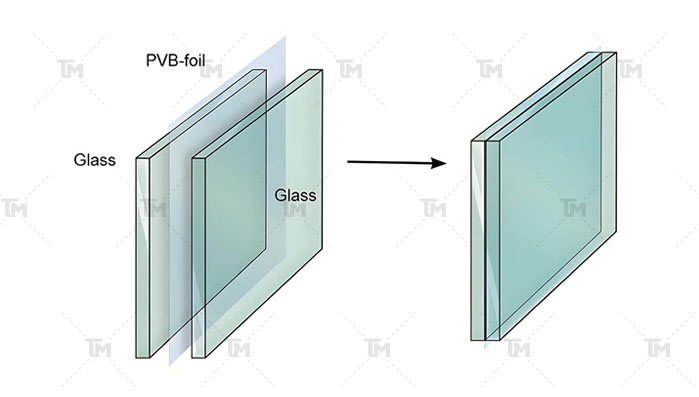

Windshield PVB film separator machine is a kind of equipment specially used for separating PVB film on car windshield. The Scrap Car Windshield Recycling Machine usually consists of multiple parts, including feeding system, separation system, collection system and control system, etc.

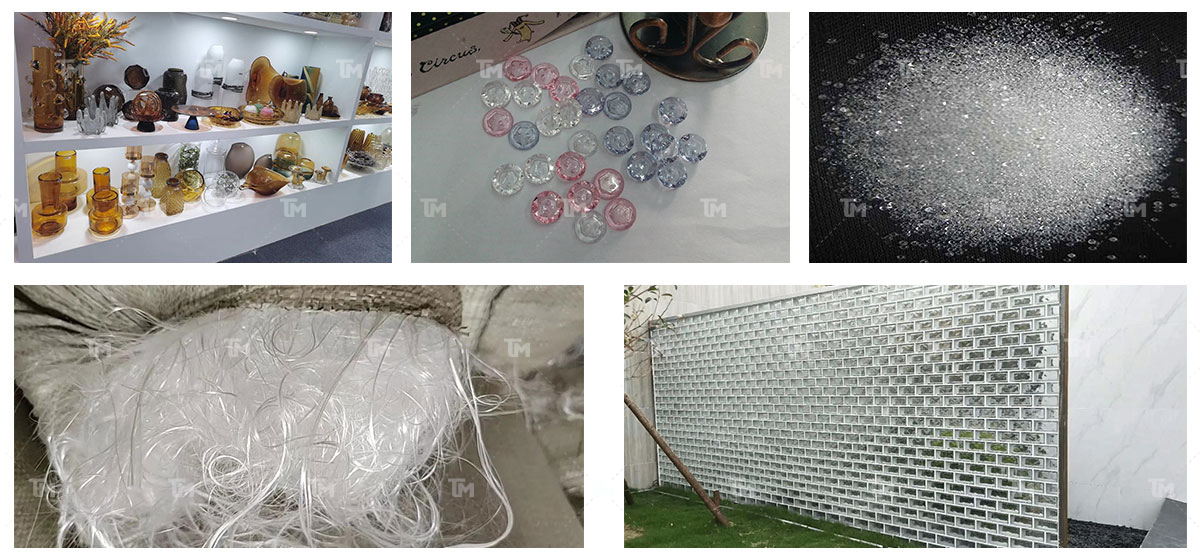

The working principle of our windshield PVB film separator is mainly based on the principle of physical mechanical screening. The whole process includes three parts: feeding, crushing and separation. In the end, broken glass with a size of <20 mm and a PVB film with a completeness rate of >98% can be obtained.

When a car is scrapped or repaired, or when a windshield is manufactured or replaced, damaged windshields will be produced. These windshields can also be recycled through a windshield PVB film separator to achieve resource reuse.

1. High efficiency: The equipment can quickly and accurately separate the PVB film from the glass body, improving work efficiency.

2. Environmental protection: The equipment can reduce environmental pollution and promote resource recycling by processing waste windshields.

3. Automation: The equipment usually adopts an automated control system, which reduces the difficulty and cost of manual operation.

4. Safety: The equipment is reasonably designed, easy to operate, and has high safety.

Environmental protection and sustainable development: If used windshields are not properly handled, they may pollute the environment. Recycling through a windshield PVB film separator can not only reduce the environmental pollution caused by used windshields, but also achieve resource recycling and reuse of used windshields.

Scientific research and technological innovation: After being crushed and separated, used windshields may produce high-quality PVB films and glass materials, which can provide new ideas and directions for materials science research and help promote research and innovation in the field of materials science.

|

Model |

TM-200 |

|

Weight(kg) |

700 |

|

Size(mm) |

2150*1000*1500 |

|

Maximum machining size(mm) |

3000*1500*50 |

|

Minimum machining size(mm) |

10*10*10 |

|

Processing thickness range(mm) |

3-50 |

|

Power(kw) |

4 |

You can leave a message online, we will contact you asap, you can conctact us by email or whatsapp also.