Lead Acid Battery Recycling Machine is suitable for recycling all kinds of lead-acid batteries, such as automotive battery, truck battery, electric bicycle battery, etc. The system uses water in a closed-loop, ensuring no water pollution.

Input: Used lead-acid batteries

Output: Lead ingots,Refined lead with purity levels of 99.9% to 99.99%, plastic granulates,clean water and Sulfuric acid crystals

Capacity: , with customized capacities available.

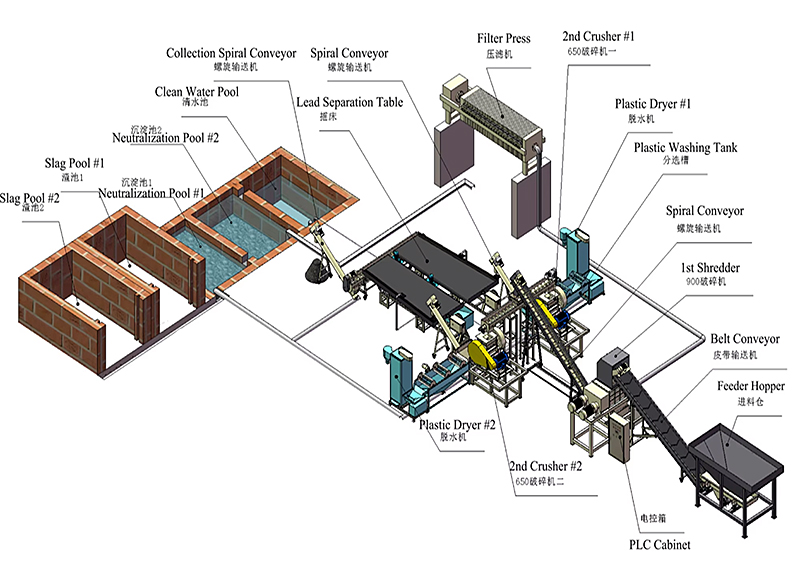

We can customized the completed Lead Acid battery recycling plant consisting of follow steps: 1. Battery Breaking and Separation System; 2. Paste Desulfurization; 3. Lead Melting And Reduction Operation of Paste; 4. Melting of Grid; 5. Refining Crude Lead; 6. Slag Treatment; 7. Plastic Cleaning; 8. Gas Purifier System; 9. Acid Neutralize and Effluent Treatment

Battery recycling plant is based on the advanced and reasonable mechanism process that can separate the LEAD and plastic from lead-acid battery. The recovery rate of lead can get 98%.

This process is an ECO-friendly method instead of pollution way that is based on burning and chemical processing.

This battery recycling plant, with working process from inlet of waste battery to recycled LEAD, consists of battery auto-cutter, lead acid bucket, primary crush (intelligent shredder MX), vibration screen, belt conveyor, secondary crush (battery crusher), washing tank, surge hopper, screw conveyor, gravity separation table (shaking table).

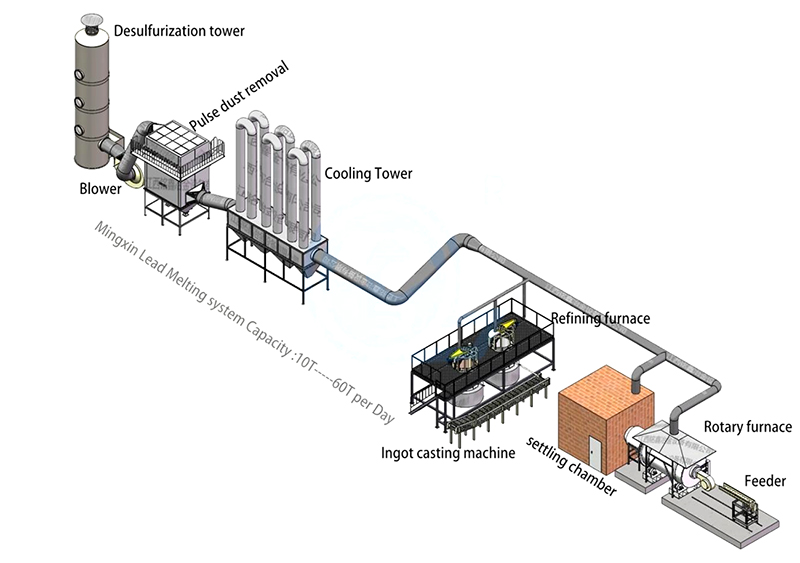

In this system, we recommend using a rotary furnace with high smelting purity, short smelting cycle and low energy consumption as the main furnace of lead-acid battery roughing. Converter fuel can be coke, natural gas, electricity, etc. We have three recommended converters with different output, 2 tons per furnace, 3 tons per furnace, and 5 tons per furnace with different specifications.The entire smelting system also includes refining pots, ingot casting machines, and dust removal and purification systems for each furnace body, so that the entire smelting process is environmentally friendly and pollution-free to produce lead ingots with a purity of 95%.

High strength: Lead smelting kettles|pots have high yield strength and tensile strength, which can meet the working pressure requirements of various pressure vessels.

Strong corrosion resistance: Lead smelting kettles|pots have good corrosion resistance and can operate stably for a long time in harsh working environments.

Thermal performance stability: Lead smelting kettles have good thermal conductivity, low thermal expansion coefficient and high heat capacity, which enable them to withstand extreme temperature changes without affecting their structural integrity.

Lead Acid Battery Recycling Machine is suitable for recycling all kinds of lead-acid batteries, such as automotive battery, truck battery, electric bicycle battery, etc.

The final products of Lead Acid Battery Recycling Machine are lead and plastic shell.

Lead

Plastic

Graphite

You can leave a message online, we will contact you asap, you can conctact us by email or whatsapp also.