There are currently three methods for recycling waste photovoltaic panels: crushing and grinding, pyrometallurgical cracking and carbonization, and chemical wet extraction.

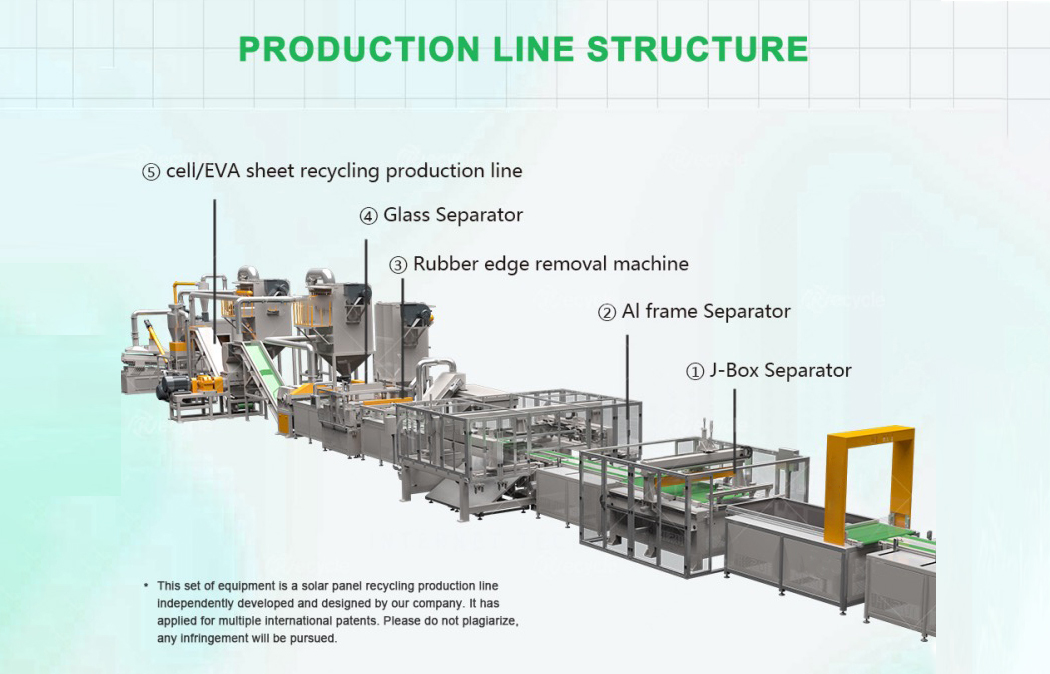

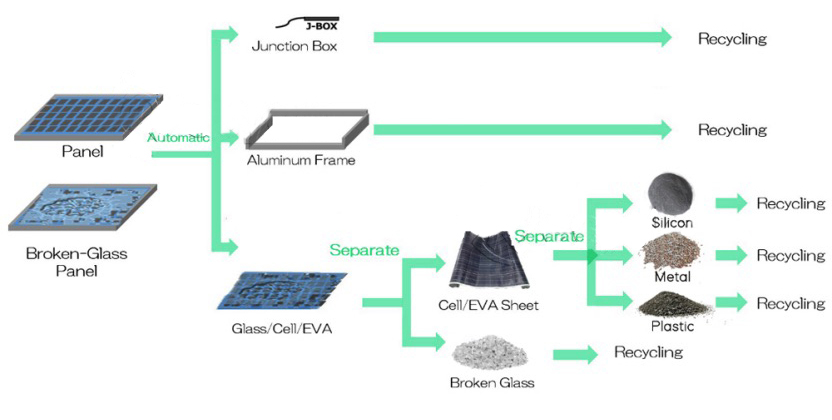

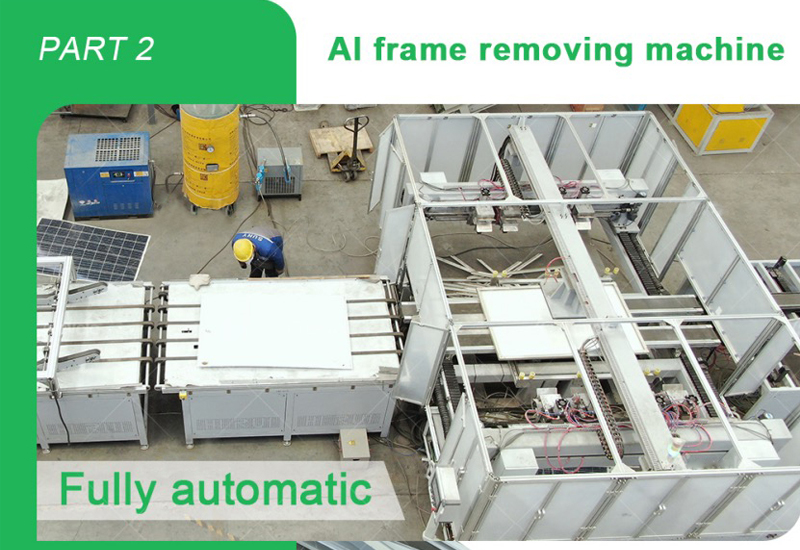

The crushing and grinding method first automatically disassembles the waste photovoltaic panels, removes the aluminum frame glass

The material sorting and recovery rate of the crushing and grinding method is approximately 93-95%

There are currently three methods for recycling waste photovoltaic panels: crushing and grinding, pyrometallurgical cracking and carbonization, and chemical wet extraction.

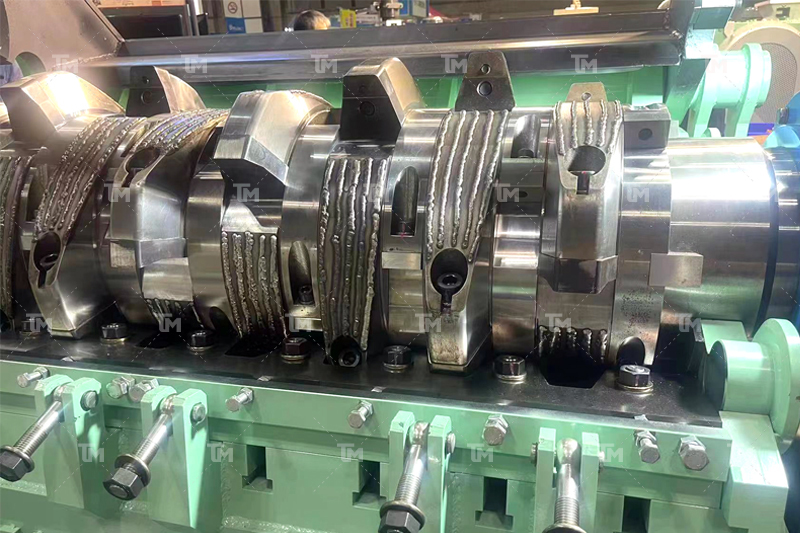

The crushing and grinding method first automatically disassembles the waste photovoltaic panels, removes the aluminum frame glass, and then enters the shredder for coarse crushing. The coarse crushed material enters the crusher and is crushed into 10mm small particles. After crushing, the material enters the grinder for grinding, and the particle size of the ground material is screened in the rotary vibrating screen. According to the different densities of the material, it enters the specific gravity sorting machine for sorting. One outlet of the sorting machine is clean copper particles, and the other outlet material is a mixture of EVA plastic and silicon silver. The mixed material enters the high-voltage electrostatic sorting machine to select clean EVA plastic and silicon silver mixture. The material sorting and recovery rate of the crushing and grinding method is approximately 93-95%

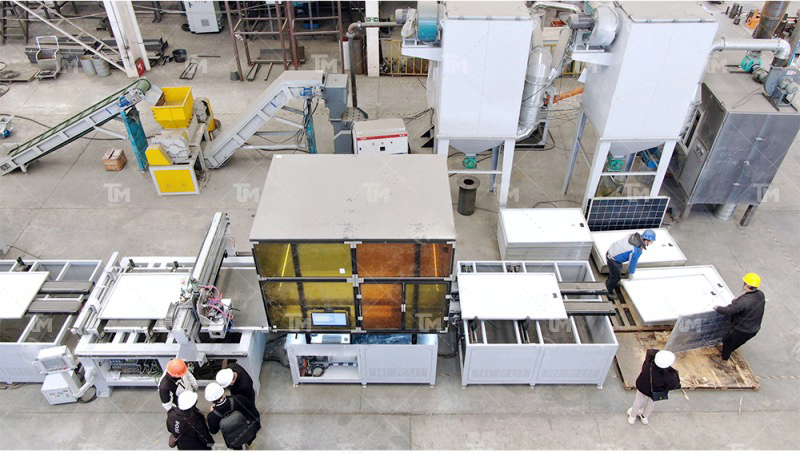

Pyrolysis carbonization first disassembles the waste photovoltaic panels, removes the frame and glass, and after crushing, puts the reduced size raw material particles into the cracking furnace. The carbonization temperature is 500 degrees, and the EVA plastic adhesive on the photovoltaic panel is removed by heating and burning. After the raw material is cracked, a mixture of copper and silver silicon wafers is obtained. The materials with different densities are sorted to obtain clean copper bars, silver, and silicon wafers. The finished particles obtained by the cracking process have a high utilization rate, with an aluminum recovery rate of 100%, a copper recovery rate of 98%, and a silicon wafer and silver recovery rate of 97%. The advantage is high recovery rate, but the disadvantage is that there is odor generated during the cracking process, which requires supporting waste gas removal equipment to assist production.

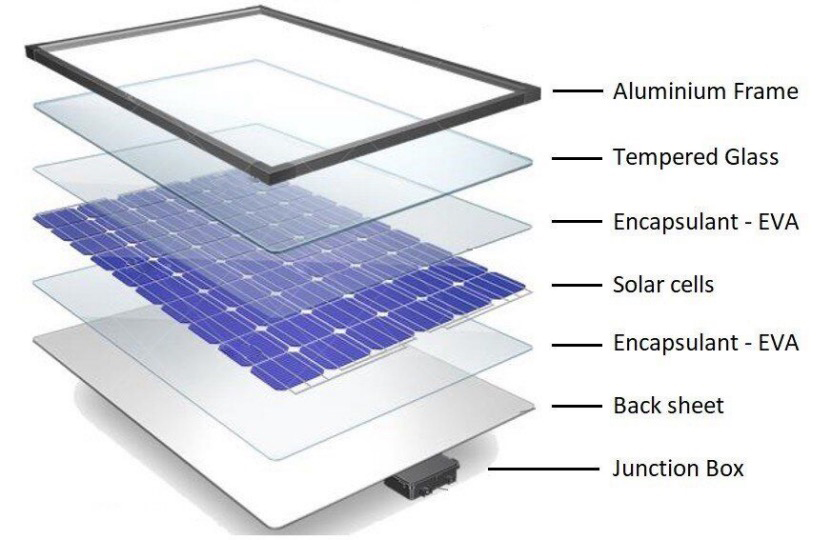

Aluminium Frame–Tempered Glass—Encapsulant- EVA—Solar cells—Encapsulant – EVA—Back Sheet—Junction Box

We can Recycle Metal( Copper, Silver etc), Silicon, Plastic and Glass from the Whole Process.

The rest of the components in a solar panel consist of good quality glass, aluminium frames, polymers, silicon, copper and silver paste (used for the printed conductors on each cell), all of which (up to 95%), can in principle be successfully recycled.

You can leave a message online, we will contact you asap, you can conctact us by email or whatsapp also.