The whole set of radiator disassembly equipment consists of two machines, a sawing machine and a radiator separator machine.

Power (kw): 2.2-3(+4)

Capacity (kg/h): 300-450

Weight (kg): 150-680

The whole set of radiator disassembly equipment consists of two machines, a sawing machine and a radiator separator machine. The radiator fins are first cut into suitable sizes by the sawing machine, and then dismantled and separated by the dismantling machine. The dismantling machine has a blade made of special steel, which is aimed at the gap of the radiator to cut and crush, and separate the copper tube, aluminum sheet and a small amount of iron. The operation is simple and convenient. One worker can process 300-450KG of raw materials per hour, which is suitable for medium and small purchasing stations.

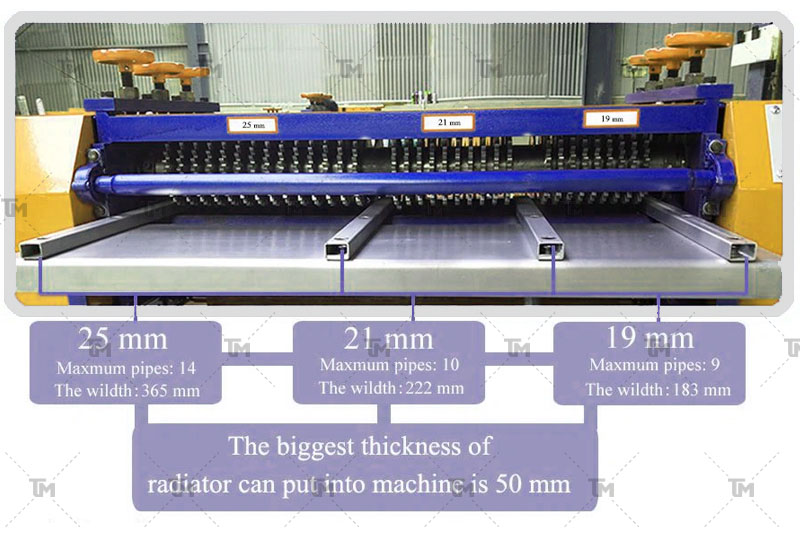

Our radiator separator machine can process 3 kinds of copper tube with different center distance at most. Most of the scrap radiators in the market are 19mm, 21mm, and 25mm. If your radiator has other distance, please tell us. We will customize the separator machine for you.

1. Regular inspection: Regularly inspect the radiator dismantling machine, including tool wear, conveyor operation, etc.

2. Cleaning and maintenance: Regularly clean and maintain the equipment, including cleaning the residue on the tool, lubricating the transmission parts, etc.

3. Repair and replacement: When the equipment fails or is damaged, repair or replace the damaged parts in time.

4. Training and operation: Train the operators to make them familiar with the equipment’s operating procedures and precautions to ensure the safe operation of the equipment.

The radiator dismantling machine can maintain the original block shape of the radiator during the dismantling process, so that the separated copper and aluminum metals still remain in a large block shape, which is convenient for subsequent processing and treatment.

The radiator dismantling machine is usually an independent device, and the dismantling work can be completed without other auxiliary equipment, thereby reducing the equipment cost and operation complexity.

The radiator dismantling machine has a high separation speed, which can quickly separate the copper and aluminum metals inside the radiator, improving work efficiency.

The radiator dismantling machine does not produce harmful substances during the dismantling process, which is environmentally friendly. At the same time, the dismantling equipment has high working efficiency and low energy consumption.

The radiator dismantling machine is not only suitable for dismantling radiators, but also can be used to dismantle other similar metal structural parts, with certain versatility and flexibility.

|

Parts |

Power (kw) |

Dimension (mm) |

Capacity (kg/h) |

Weight (kg) |

|

Sawing Machine |

2.2 |

1000*550*1800 |

— |

150 |

|

Main Machine |

3+4 |

1800*900*1250 |

300-450 |

680 |

You can leave a message online, we will contact you asap, you can conctact us by email or whatsapp also.