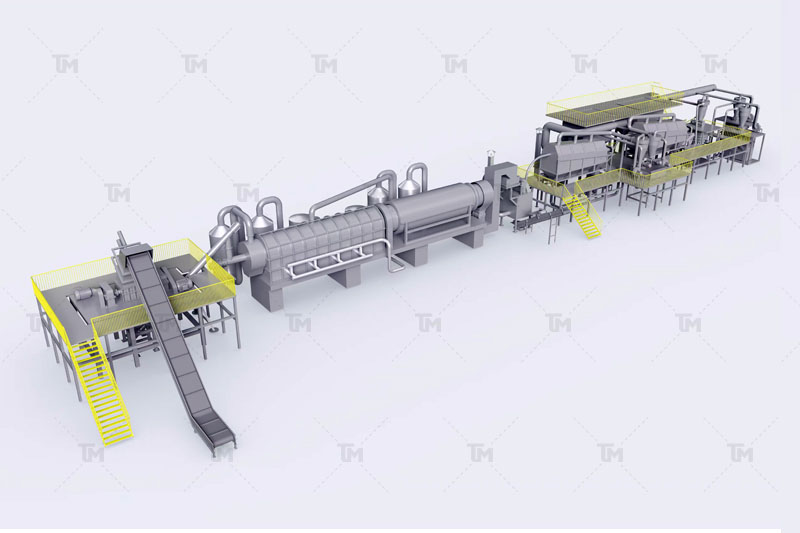

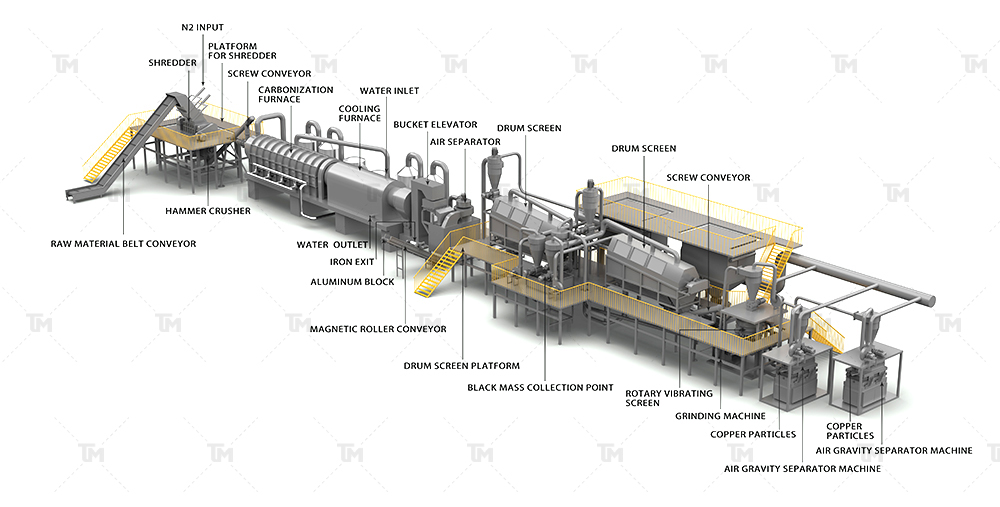

The pretreatment process of scrap lithium batteries is mainly to recycle waste batteries,after discharging(with charging),mechancial equipment is used to break,magnetic separation,air separation,crushing gravity separation,screening

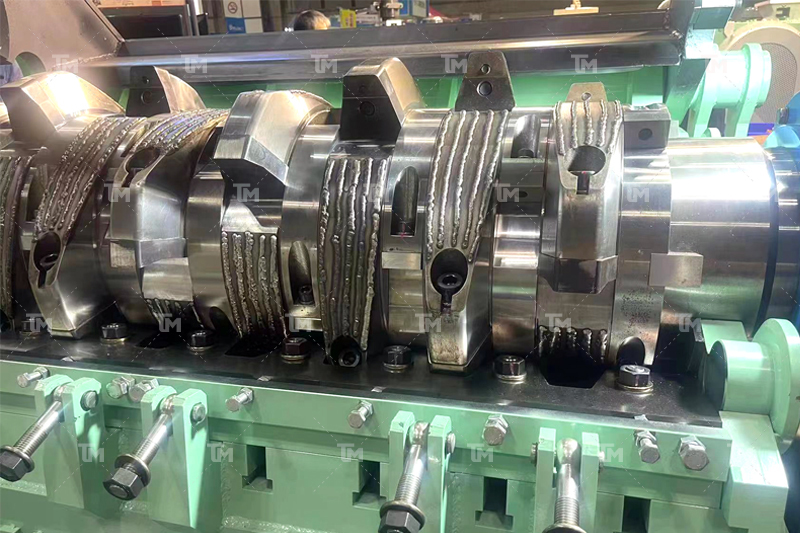

The carbonization heater is configurated mainly for the plastic,glue,electrode ect removing

The powder on the anode and cathode can be effectively separated from copper and aluminum foil.

Before we design the suitable solution for u and pls confirm which battery model u will plan to process or recycling? LCO?NMC?LFP? Since process different kinds of batteries and will have some risks of explosion.but no worry and we can handle this issue safety.

Lithium battery mainly consists of shell,positive electrode,positive electrode,negative electrode,electrolyte and diaphragm,the positive electrode is formed by coating lithium cobalt powder on two sides of an aluminum foil current collector through PVDF which plays a bonding role,the negative electrode structure is similar to the positive electrode and consists of carbon powder bonded to both sides of the copper foil current collector,

At the present,the research on the recycling of waste lithium battery is an important production raw material widely used,carbon powder adhered to it can be used as additives such as plastics and rubber,based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process tp realize efficient separation and recovery of waste lithium batteries.

The pretreatment process of scrap lithium batteries is mainly to recycle waste batteries,after discharging(with charging),mechancial equipment is used to break,magnetic separation,air separation,crushing gravity separation,screening and other processes,so that the powder on the anode and cathode can be effectively separated from copper and aluminum foil.

The carbonization heater is configurated mainly for the plastic,glue,electrode ect removing. Diaphram paper will be cracked into flammable gas in the furnace to burn,the plastic shell material can not be removed this part and will output with other material and be separated at the shell material separating part.

At the same time,in this way,the fluorhydric acid can also be removed after the heater.the organic gas will be burned and be purified during the processing,the output would be the inorganic gas to reach the emission standard, after this processing,the diaphram plastic,glue,fluoridric acid etc will be fully removed and will go forward by the future physical separation.

waste lithium batteries

waste lithium batteries

waste lithium batteries

scrap iron(shell)

aluminium|copper

carbon powder

You can leave a message online, we will contact you asap, you can conctact us by email or whatsapp also.